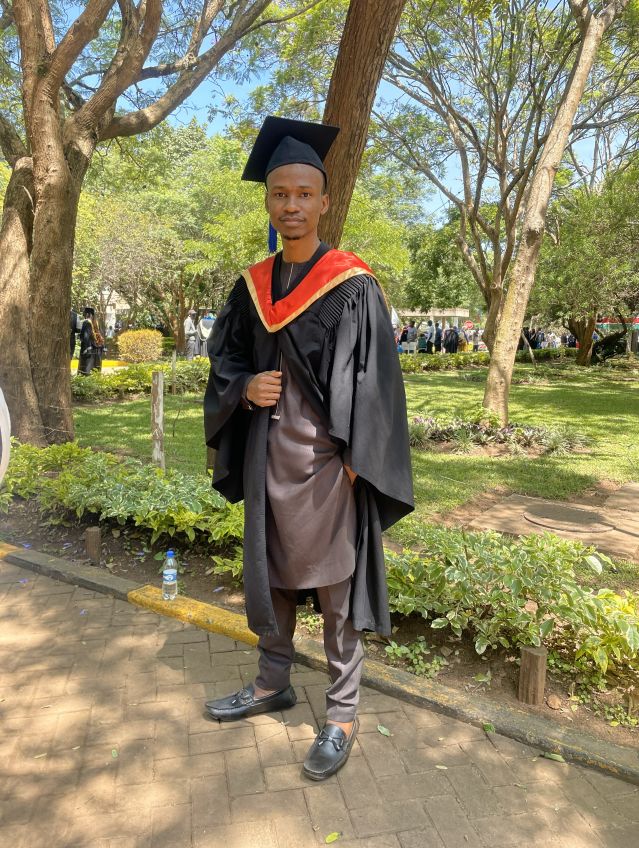

Hi, I'm Emmanuel the Mechatronics Engineer

Technical specialist in industrial automation, mechatronics, smart manufacturing and system optimization.

Currently studying Masters in Mechanics - Technische Universität Darmstadt, Germany.

.jpg)

Years Experience

Projects Delivered

Winner JKUAT Tech Expo 11.0

Automation Systems

PLC programming, HMI design, diagnostics, and production line optimization.

Robotics Integration

Industrial robots, safety systems, commissioning, and performance tuning.

Smart Maintenance

Sensor data, condition monitoring, and predictive maintenance strategies.

🏆 Breakthrough Project

Robotics Integration

The automated aquaponics system using IoT, was a robotics intergration breakthrough, designed to optimize fish and plant growth through automated monitoring and control of environmental parameters. I had designed a fully autonomous system that could be monitored remotely. A project that won the JKUAT Tech Expo 11.0 competition and earned national recognition at KENIA innovation week. The project was a holistic combination of robotics, IoT, using: HMI for user interface, phone application for remote monitoring, raspberry PI microprocessor and linux system for optimization. Robotic production lines with safety, diagnostics and optimization.

.jpg)

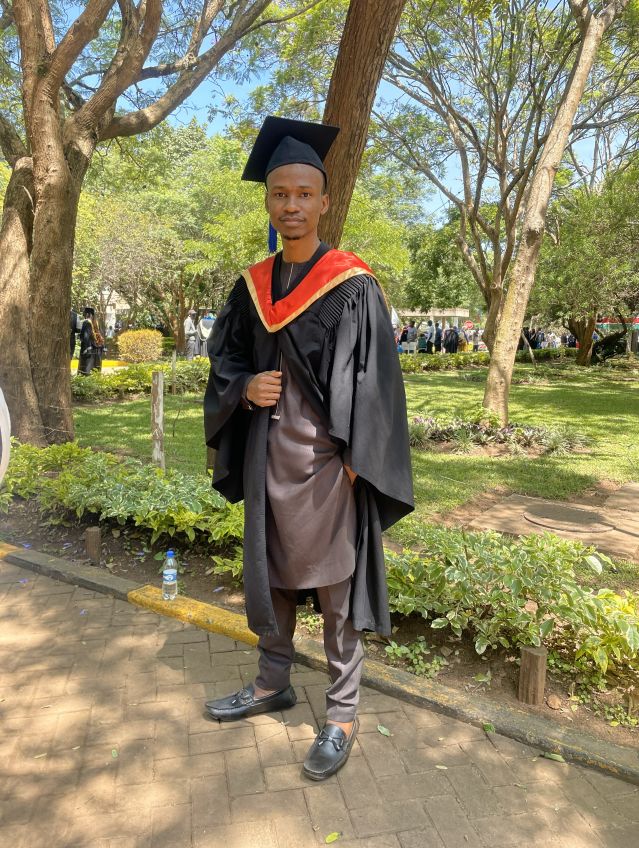

Emmanuel

“ ”In an era where information is abundant, I believe the true value lies in the ability to distill complex data into actionable insights that drive efficiency and innovation. My journey has been fueled by a relentless curiosity and a commitment to excellence, enabling me to tackle challenges head-on and deliver solutions that not only meet but exceed expectations.

Machines fail from dirt, wear and tear, and unforeseen issues. My goal is to leverage technology to predict and prevent these failures.

🛠️Work Experience 🛠️

Primary Manufacturing Processes

Demonstration of capabilities in primary manufacturing processes which include: machining, assembly, and quality control. The photos depict my hands-on experience in Tinning of journal bearings and assembling of turbine parts at the Olkaria Geothermal Power Plant.

Predictive Maintenance

Imagine a factory where machines can predict their own breakdowns before they happen, through Sensor-based monitoring and data-driven maintenance strategies. That's what I specialize in, using vibration meters and routine lubrication inspection analysis to achieve predictive maintenance. A huge part of loss elimination in manufacturing. Sensor-based monitoring and data-driven maintenance strategies

Fun Facts – Do You Know?

“ ”Emmanuel has worked at the Olkaria Geothermal Power Plant, home to the largest single-turbine unit on the continent, at 83.3MW — contributing to clean, renewable energy generation. 😉

He has also gained experience working with British American Tobacco, a global manufacturing organization operating in over 180 markets worldwide. 💪

Electrical Inspection

Routine electrical systems inspection and maintenance ensures operational safety and efficiency in industrial settings. I have conducted inspections involving thermal imaging, insulation resistance testing using the Megger tester.

Programming (C#, Python, ML & AI, Linux systems)

Skilled in programming languages such as C# and Python, with experience in machine learning and AI applications. Proficient in Linux systems (mint,kali&ubuntu) for development and deployment of software solutions. Worked on PCBs and embedded systems for industrial applications, using microprocessors like: STM32 and Raspberry Pi. Used LSTM and CNN models for predictive maintenance tasks.

SAP, MS Office Skills & PowerBI

Proficient in SAP for maintenance management, MS Office for reporting, and PowerBI for data visualization. I have created detailed maintenance reports, dashboards, and analytics to support decision-making and improve operational efficiency.

SMP, IWS and Kaizen Developments

Experience in implementing Secondary Manufacturing Practices (SMP) and Intergrated Work Systems (IWS) to enhance operational efficiency and productivity. Through IWS experience in BAT, I have contributed to streamlining workflows, reducing waste, and improving overall manufacturing processes.

Testimonials

“Emmanuel showcased very self-driven behaviours during his assignment in module 2. He has the right capabilities of solving problems to the root cause.”

“Emmanuel's reapplications and Kaizen developments as part of his autonomous maintenance role brought more teamwork and created a good forum for usage of problem solving tools.”

Career Timeline

Msc. Mechanics -Technische Universität Darmstadt

2025 – Present

Industrial automation, PLC programming, robotics integration, diagnostics and production optimization.

Mechatronics Technician - British American Tobacco

2023 – 2024

Loss Elimination, Speed up CBA, Electrical systems troubleshooting, mechanical maintenance, sensor calibration and documentation.

MechatronicsIndustrial Apprenticeship - Olkaria Geothermal Power Plant

2022 – 2023

Hands-on training in industrial mechanics, safety procedures, and production support. Routine maintenance and inspection, ensuing GMPs conditions are met.

Photo Gallery

Let’s Build Something Meaningful

I enjoy working on systems that are reliable, efficient, and built to last — from industrial automation to predictive maintenance and robotics integration.

“Great engineering is invisible — systems work quietly, reliably, and efficiently.”

Note: Interested in this portfolio layout or want something similar built for you? Reach out — I’m happy to help design and build a personalized version.